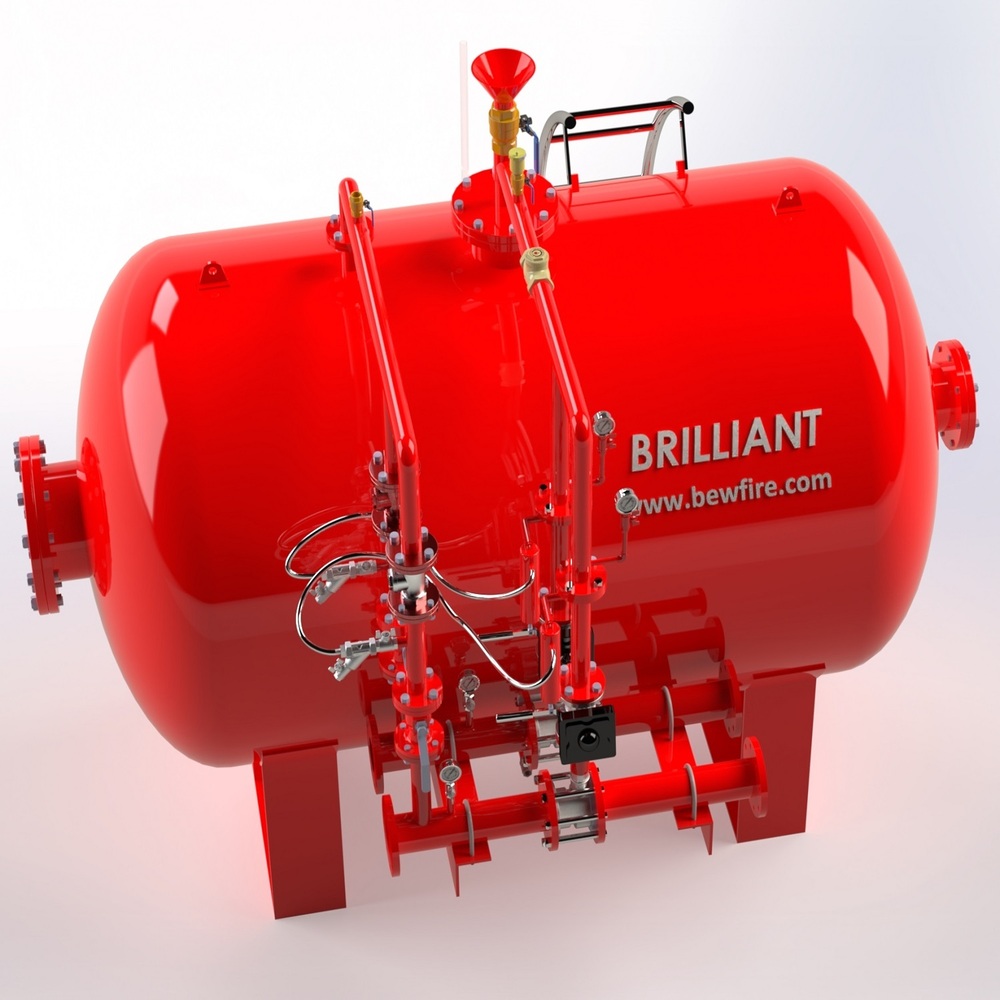

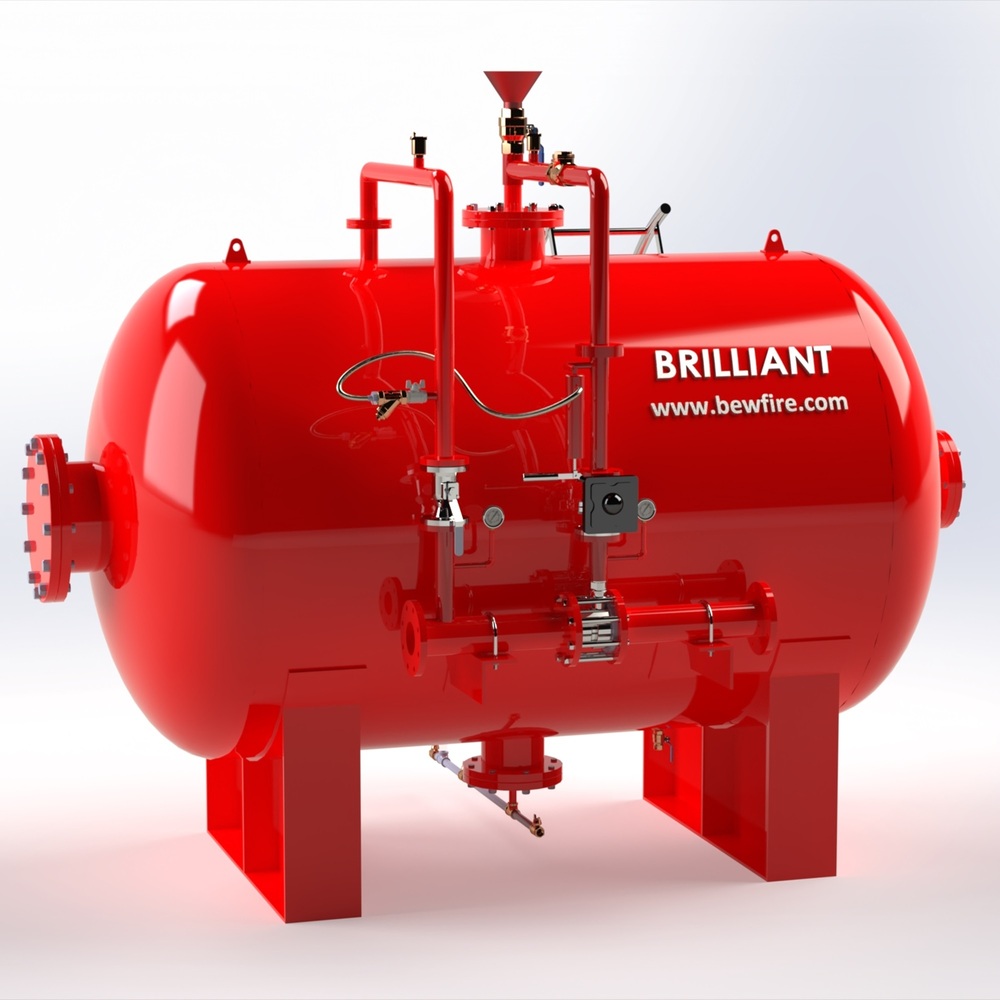

Vertical Foam Bladder Tank

350000.0 INR/Piece

Product Details:

- Energy Efficiency Rating Not applicable (passive device)

- Installation Type Vertical, floor-mounted

- Technology Bladder Tank Foam Proportioning System

- Features Corrosion resistant, low maintenance, easy installation

- Shape Vertical cylindrical

- Fire Class A & B

- Coating Type Epoxy coated

- Click to View more

X

Vertical Foam Bladder Tank Price And Quantity

- 350000.0 INR/Piece

- 1 Set

Vertical Foam Bladder Tank Product Specifications

- Floor mounting

- Brass

- 800 mm (approximate, based on standard models) Millimeter (mm)

- -10C to +50C Celsius (oC)

- Flanged connections

- Manual & Automatic

- Foam Suppression System

- For Fire

- Up to 12000 LPM (liters per minute)

- Vertical, floor-mounted

- Not applicable (passive device)

- Epoxy coated

- Bladder Tank Foam Proportioning System

- Corrosion resistant, low maintenance, easy installation

- Vertical cylindrical

- A & B

Vertical Foam Bladder Tank Trade Information

- JNPT NHAWA SHEWA

- Telegraphic Transfer (T/T)

- 10000 Set Per Month

- 1 Days

- EXPORT QUALITY PACKING

- All India

- CE CERTIFIED

Product Description

Technical Specification:-

Tank capacity : 200 to 20000 Litres

Tank Material : Stainless Steel / Carbon Steel /ASTM A 516 GR. 70

Foam Proportioner Size : 65NB to 200 NB

Material of Construction :-

|

SR. NO |

DESCRIPTION |

MATERIAL |

|

1) |

Thermal Relief Valve |

Brass |

|

2) |

Tank |

ASTM A 516 GR. 70 |

|

3) |

Tank Pressure Guage |

Stainless Steel |

|

4) |

Foam Concentrate Shut Off Valve |

SS304 |

|

5) |

Water Shut Off Valve |

SS304 |

|

6) |

Ratio Controller |

SS304 |

|

7) |

Water Drain Valve |

BRASS |

|

8) |

Foam Level Indicator |

POLY CARBONATE |

|

9) |

Foam Concentrate Fill/Drain Valve |

BRASS |

|

10) |

Analog Level Indicator |

SS304 |

|

11) |

Foam Orifice |

SS304 |

|

12) |

Water Vent Valve |

BRASS |

|

13) |

Foam Vent Valve |

BRASS |

|

14) |

Non Return Valve |

SS304 |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese